Our Location: Plaza 2000, First Floor, Mombasa Road, Nairobi

-

Agitator Tanks

Agitator tanks are fabricated using stainless steel and feature various types of agitators, each designed to provide different mixing effects. Common agitator types include paddle agitators, turbine agitators, anchor agitators, and propeller agitators. Agitator tanks come in various shapes, such as cylindrical, conical, and rectangular.

The tank’s design influences factors such as mixing efficiency, circulation patterns, and ease of cleaning. The agitator tanks can be equipped with control systems that allow operators to adjust agitation speed, temperature, and other parameters. Automation can enhance process control and repeatability.

-

Band Saws

Band saws are constructed with stainless steel and can cut a wide range of materials, including wood, metal, plastic, and more. This versatility makes them suitable for various applications in different industries. The band saws typically produce smoother cuts compared to other band saws, resulting in less need for additional finishing work.

-

Batch Fillers

The batch fillers allow for adjustable fill sizes, accommodating a range of container sizes and fill volumes. This flexibility is useful when packaging different products or adjusting to changing production needs.Batch fillers can handle a wide variety of products, including liquids, powders, granules, creams, gels, and more.

The adaptability to different product types makes them suitable for diverse industries. Specialized features such as drip trays, anti-drip nozzles, and vacuum systems help minimize product spillage and maintain a clean production environment.

-

Beverage

Beverage processing begins with the preparation of high-quality ingredients. Our water treatment systems remove impurities and ensure that the water meets the stringent standards required for beverage production. Following this, syrup is prepared by dissolving sugar and mixing it with flavorings, colorants and other ingredients. Our stainless-steel mixing tanks ensure optimal mixing effects for different beverage formulations. Formulation of ready to serve fruit drinks involves blending fruit pulp with treated water, sugar syrup and other ingredients such as citric acid and natural flavors. Our advanced blending systems ensure consistent product quality by maintaining accurate ingredient ratios and minimizing product waste. Once the beverage is formulated, it undergoes thermal processing in our pasteurization units to ensure microbial stability while preserving flavor and nutritional value. For carbonated soft drinks, the blended beverage base is cooled to the appropriate temperature to facilitate carbonation. Our carbonation systems inject carbon dioxide into the beverage under controlled conditions, achieving the desired level of fizziness and ensuring product consistency.

-

Blanchers

They are constructed with Stainless steel and are capable of achieving precise control of time and temperature. Different foods have varying blanching requirements. Generally, the blanchers can achieve temperatures around 85-100°C (185-212°F) for a short period, usually 1-5 minutes which is highly recommended.

The blachers have dainage system that removes excess moisture from the food product to prevent dilution of flavors and to facilitate further processing. Quality control can be achieved through visual inspection, testing, and quality control measures to ensure consistent product quality.

-

Boilers

Neo Eng offers a wide range of industrial boilers designed to meet the thermal energy needs of industries such as food and beverage, pharmaceuticals, chemicals, oil and gas, power generation, and manufacturing.

The boilers are fabricated with stainless steel and have advanced control systems that regulate temperature, pressure, and other parameters. The boilers are powered with LPG gas, which has high efficiency, lower emissions, and low operational costs. Features like easy access to components and self-diagnostic systems can simplify maintenance and hence improve productivity and longevity.

The boilers are designed with a focus on reducing emissions and environmental impact. This can include lower harmful gases emissions and compliance with emission regulations.

-

Buffer Tank

It is a storage tank used on the cold user side as a storage or to cover peak loads or in situations when a surge in demand exceeds the capacity.

-

Bulk Blender

Bulk blenders are constructed with stainless steel. They come in various sizes and capacities to accommodate different volumes of products.They are versatile and can handle a wide range of materials, from food ingredients and pharmaceutical powders to chemicals and industrial compounds. Their flexibility allows them to be used across various industries.

One of the most important characteristics of bulk blenders is their ability to achieve uniform mixing. They are engineered to ensure that all components are evenly distributed throughout the mixture, resulting in consistent product quality and properties.

-

Bulk Blenders

Bulk bleners are constructed with stainless steel. They come in various sizes and capacities to accommodate different volumes of products.They are versatile and can handle a wide range of materials, from food ingredients and pharmaceutical powders to chemicals and industrial compounds. Their flexibility allows them to be used across various industries.

One of the most important characteristics of bulk blenders is their ability to achieve uniform mixing. They are engineered to ensure that all components are evenly distributed throughout the mixture, resulting in consistent product quality and properties.

-

Bulk Cooling Tanks

A bulk cooling tank is the heart of your cold chain, designed to keep perishables fresh, safe and market ready. Perfect for dairy processors and other temperature sensitive operations, our tanks are built from food grade stainless steel and are engineered for fast, consistent and energy-efficient cooling. Each unit is built for durability and comes with user friendly temperature controllers and a hygienic, easy to clean finish. We build each unit in house, giving you full control over capacity, layout and automation preferences.

-

Centrifuges

Neo Eng offers advanced centrifuge solutions across a broad spectrum of industries including dairy, beverage, brewing, starch, edible oil and protein processing. In dairy applications, our centrifuges are used for cream separation and milk clarification, effectively removing impurities such as somatic cells, dirt and bacteria. In beverage processing, they enable juice clarification, pulp separation and sediment removal to ensure a clean, refined end product. They are also instrumental in the beer clarification process including pre-clarification, green beer separation and beer recovery. Our centrifuge systems are engineered for high throughput and precision, making them ideal for continuous production environments. They feature stainless steel construction, clean-inplace (CIP) capabilities and minimal product retention. The enclosed operation reduces contamination risks, ensuring compliance with strict food safety standards. Automated control systems allow real-time adjustments to separation speed, bowl discharge frequency and flow rates.

-

Chilled Water Piping

Efficient chilled water piping is essential for temperature control in food, beverage and pharmaceutical production environments. Our systems are designed to ensure consistent cooling performance while minimizing energy loss and condensation risks. We supply and install highgrade and pre-insulated piping systems for chilled water distribution. These lines are routed strategically to support critical equipment like heat exchangers and process tanks. All pipework is installed with proper slope and expansion allowances. We also offer glycol-compatible systems for sub-zero applications, complete with correctly sized pumps, flow control valves, strainers and temperature sensors.

-

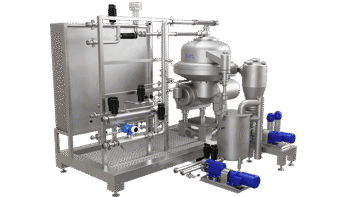

CIP Modules

Cleaning-in-Place (CIP) modules are essential for maintaining hygiene, safety and regulatory compliance in food and pharmaceutical production. These systems automatically clean processing equipment such as tanks, pipelines and heat exchangers without dismantling, reducing downtime and manual intervention while ensuring safety standards are met. At Neo Eng, our CIP systems are engineered for performance, reliability and seamless integration. Each unit features stainless steel detergent and rinse tanks, properly sized balance tanks for consistent flow and high-efficiency centrifugal pumps that provide the pressure and turbulence required for effective cleaning. Heat exchangers integrated with steam to maintain precise cleaning temperatures, while automated valves and sensors manage cycle transitions and monitor flow rate, temperature, pressure and conductivity. A centralized control interface enables recipe programming, data logging and system diagnostics for easy monitoring. We offer both single-circuit and multi-circuit designs depending on plant layout and cleaning requirements. For added safety and clarity, all piping is coded and fitted with sanitary connections.

-

Clapboard Elevators

A clapboard elevator is the gentle lifter every food-processing line needs. It is made up of a series of flat plates (clapboards) mounted on a stainless-steel chain that scoop up produce or bulk ingredients, carry them vertically or on a shallow incline and discharge them without bruising or blockage. At Neo Eng, we build these units from food-grade materials and durable, easy-clean clapboards that are fully welded and polished. Variable-frequency drives let you dial in speeds from a whisper for delicate berries to a brisk pace for hearty root vegetables, while the intermittent plate action prevents blockages and keeps flow consistent. Mounted on robust frames with minimal lubrication bearings, our elevators require little maintenance yet stand up to daily wash-downs and heavy use. They are configured in horizontal, inclined or combined layouts with multiple feed and discharge points and come in sizes that fit any footprint.

-

Cold Rooms – Commercial Refrigeration Solutions

Our Cold Room refrigeration units are the perfect solution to keep your products fresh and cool. Having been the leaders in commercial refrigeration, we have a wide range of products catering to various small and large scale industries. We offer the best commercial Refrigeration solutions in Kenya. We have been a major supplier of Commercial Refrigeration, Kitchen Appliances, and coffee machines in the Eastern and Central Africa markets serving restaurants and other food service businesses. We offer expert supply and installation of commercial Kitchen equipment with professional after sale support.

Cold rooms are designed and fabricated from stainless steel and proper insulation materials to maintain specific temperature ranges, usually ranging from refrigeration temperatures (around 0°C to 5°C) to freezing temperatures (below -18°C). Precise temperature control is crucial for preserving the quality and safety of stored items.Cold rooms come in various sizes and capacities to accommodate different storage needs. They can range from small walk-in units to large warehouse-sized cold storage facilities.

Cold rooms are constructed with high-quality insulation materials, such as polyurethane foam, to prevent heat exchange between the interior and exterior environments. Proper insulation ensures energy efficiency and temperature stability. Cold rooms are designed with hygiene in mind. Smooth and easy-to-clean surfaces, as well as proper drainage systems, help maintain a sanitary environment.

-

Dairy

Neo Eng delivers end to end dairy processing solutions designed to ensure product quality, safety and operational efficiency. Our systems cover the full value chain, from raw milk intake to the production of high-value dairy products, leveraging advanced technologies and equipment to meet the evolving demands of the industry. Raw milk is received through milk reception modules equipped with automated sampling and weighing systems, ensuring accurate intake and traceability. The milk is then cooled and stored in bulk cooling tanks to preserve its quality prior to transportation or processing. Pasteurization involves heating the milk to specific temperatures to eliminate harmful microorganisms, followed by rapid cooling. Our pasteurization units, are designed for energy efficiency and minimal product loss. Pre-pasteurization, centrifuges are utilized to divide cream and sludge from skim milk, allowing for precise standardization of fat content. The milk then undergoes separation homogenization using homogenizers that apply high pressure to break down fat globules, resulting in a uniform and stable product. In the production of value-added dairy products like yogurt, butter, ghee and cheese, process tanks and industrial kettles with precise temperature and agitation controls to facilitate product consistency. To maintain stringent hygiene standards, we implement Clean in Place systems that automate the cleaning process, reducing downtime and ensuring compliance with industry regulations. Our solutions incorporate advanced automation and control systems, enabling real-time monitoring and control of processing parameters.

-

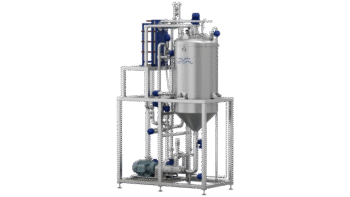

Deaerators

In our process solutions, deaerators are integrated to ensure optimal oxygen removal using a combination of vacuum and thermal techniques. The presence of oxygen in milk, juices and flavored beverages can lead to oxidation, which negatively impacts taste, shelf life, color and nutritional value. In certain systems, gentle heating is applied to enhance the deaeration effect without compromising product quality. Modern deaeration units include features like automatic control for temperature, pressure and vacuum level, ensuring consistent operation. These units are also designed for easy cleaning and are constructed from food-grade stainless steel for hygiene and durability.

-

Decanters

At Neo Eng, we integrate decanter centrifuges into various industrial processes to efficiently separate solids from liquids. Decanters use high-speed rotation to separate components based on density, allowing for continuous processing of large fluid volumes. In the edible oil sector, decanters play a crucial role in clarifying pressed oils and recovering valuable by products. They are also integral in waste water treatment for sludge thickening and dewatering, which reduce sludge volume and associated disposal costs. In rendering, decanters extract fats and oils from animal by products, improving quality of the final meal and reducing waste. Additionally, decanters are used in biofuel production to purify used cooking oils and process biomass thus supporting renewable energy initiatives. The expertise of Neo Eng in deploying these versatile decanters ensures optimized performance and reliability across various industrial applications.

-

Drainage Systems

In industrial facilities, effective drainage is essential for hygiene, safety and operational efficiency. Neo Eng designs and integrates drainage systems tailored to industries such as food and beverage, pharmaceuticals, automotive, chemical manufacturing, agriculture and logistics. Our solutions incorporate high-capacity trench drains, slot channels, floor gullies and custom drainage points to ensure rapid removal of cleaning water and product spills. These systems are constructed with smooth internal surfaces and removable components to facilitate easy cleaning and maintenance, supporting compliance with stringent safety standards. We also incorporate grease and solids traps, backflow prevention and vapor-tight seals to prevent blockages, minimize odors and protect downstream treatment systems. By aligning drainage planning early in the design phase with equipment placement, utility lines and traffic paths, Neo Eng ensures that each system effectively manages the unique challenges of its operational environment.

-

Dump Tanks

Dump tanks serve as versatile, hygienic receptacles in dairy and meat processing facilities, seamlessly integrating with built-in load cell or floor scale weighing systems to streamline product reception and transfer. Instead of manually lifting heavy totes onto scales, operators can wheel the dump tank directly beneath the discharge spout, weigh the contents in place and then dump or transfer into downstream equipment. This reduces handling steps, speeds up throughput and ensures accurate batch records for traceability and inventory control. Neo Eng dump tanks are fabricated from food grade stainless steel with fully welded seams for easy cleaning. Thick gauge walls, reinforced support frames and sanitary drain valves ensure that these tanks withstand daily impact, high-pressure washdowns and continuous use without deformation or bacterial risk. Mobility is enhanced with locking castor wheels or integrated forklift pockets, allowing safe and efficient movement from reception to mixing stations or staging areas.